During the annual RoboSub competition, Amador’s AVBotz team finished placing 5th in the Autonomy Challenge category against a majority of college teams. RoboSub, an international competition located in San Diego, brings together aspects of engineering, coding, and robotics into Autonomous Underwater Vehicles (AUVs).

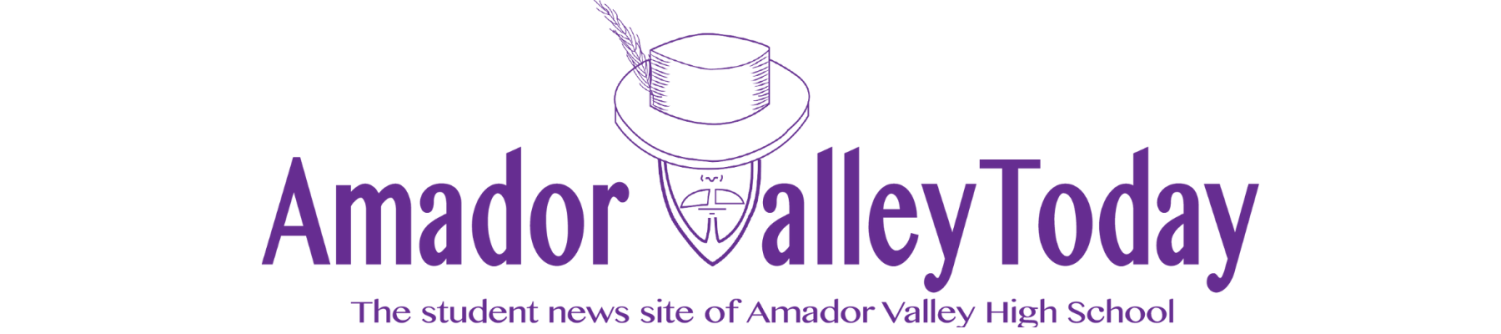

Team members specialized in various facets of the bot, spanning mechanical, software, and electrical domains. Simultaneously, some dedicated their efforts to weekly business meetings. As summer dawned, the entire team converged, investing 8 to 12 daily hours to forge competition-ready perfection.

“They are completely self-taught and they are competing at a collegiate level from the knowledge that they are able to pass on [from] juniors and seniors to the freshman and sophomores,” said club advisor Bree Barnett Dreyfuss.

AUVs use previously added programming rather than continuous operator inputs. Each of the challenges the AVBotz team must program the bot to accomplish is similar to real-world problems facing sea navigation. Each group gets an idea of hands-on software, electrical, and mechanics for robots that could be seen in the robotics field.

“The experience one gains being a member in AvBotz is extremely valuable because you get an experience actually working hands-on with an actual robot you [the team members] are creating from the ground up,” said 2023-2024 Club President Angad Bhargav (‘24).

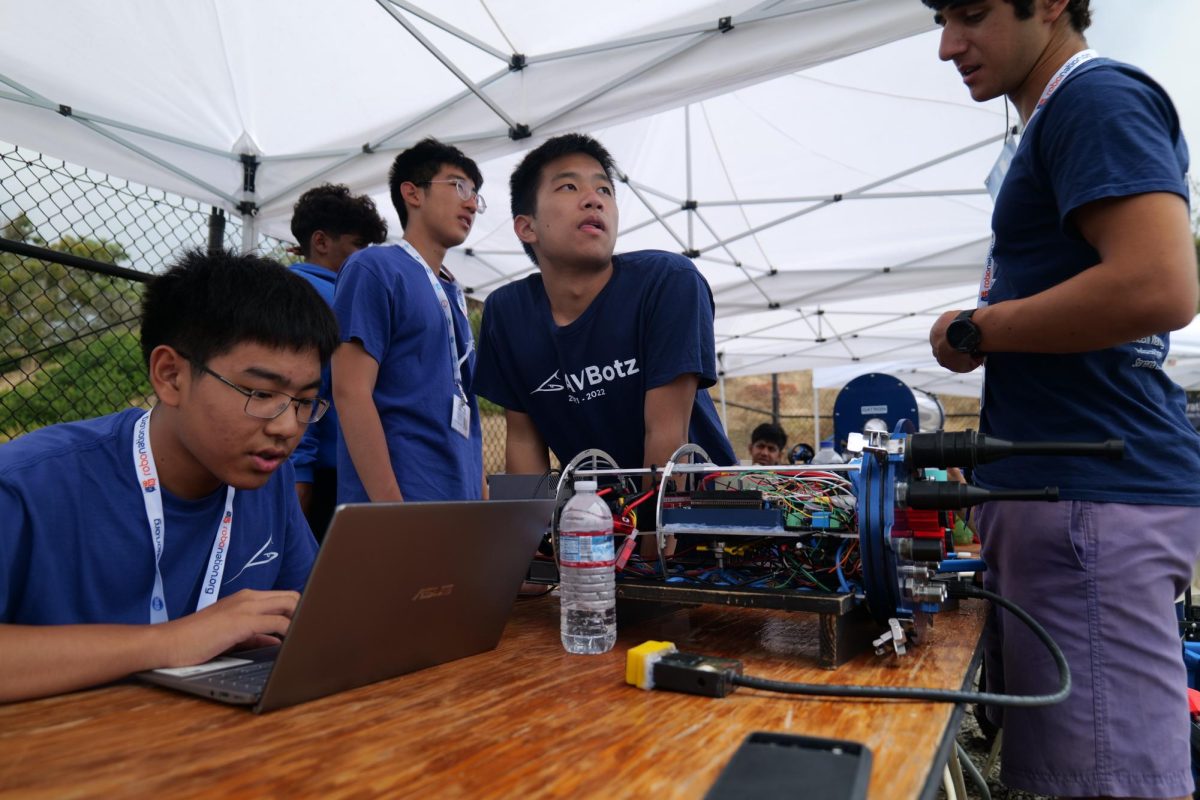

With all the components of the bot from the ground up, the base of the sub was built six to seven years ago with a completely new frame and thrusters. This year, the club faced electrical challenges, where certain components were not performing well enough with the software.

“Over the years, we have been improving and maintaining what works and also just trying to make new edits to make the sub perform better at comps. We made the frame a lot easier to edit and change throughout the year which made it a lot easier to have hotspot components and make edits really easily,” said Kaustubh Lole (‘25).

Trials occur during the competition while pre-qualifications are sent to the competition beforehand to ensure the sub works and is able to compete at the tasks. The team worked through issues with broken parts during the semi-finals.

“During the semifinals, we did really badly because a lot of our parts were broken. We fixed a lot of our parts and during the third chance we had a perfect run which allowed us to qualify for finals where we finally placed 5th,” said Aarav Singh (‘25).